Loading library...

Processes - Mechanical Finishing

Mechanical Finishing

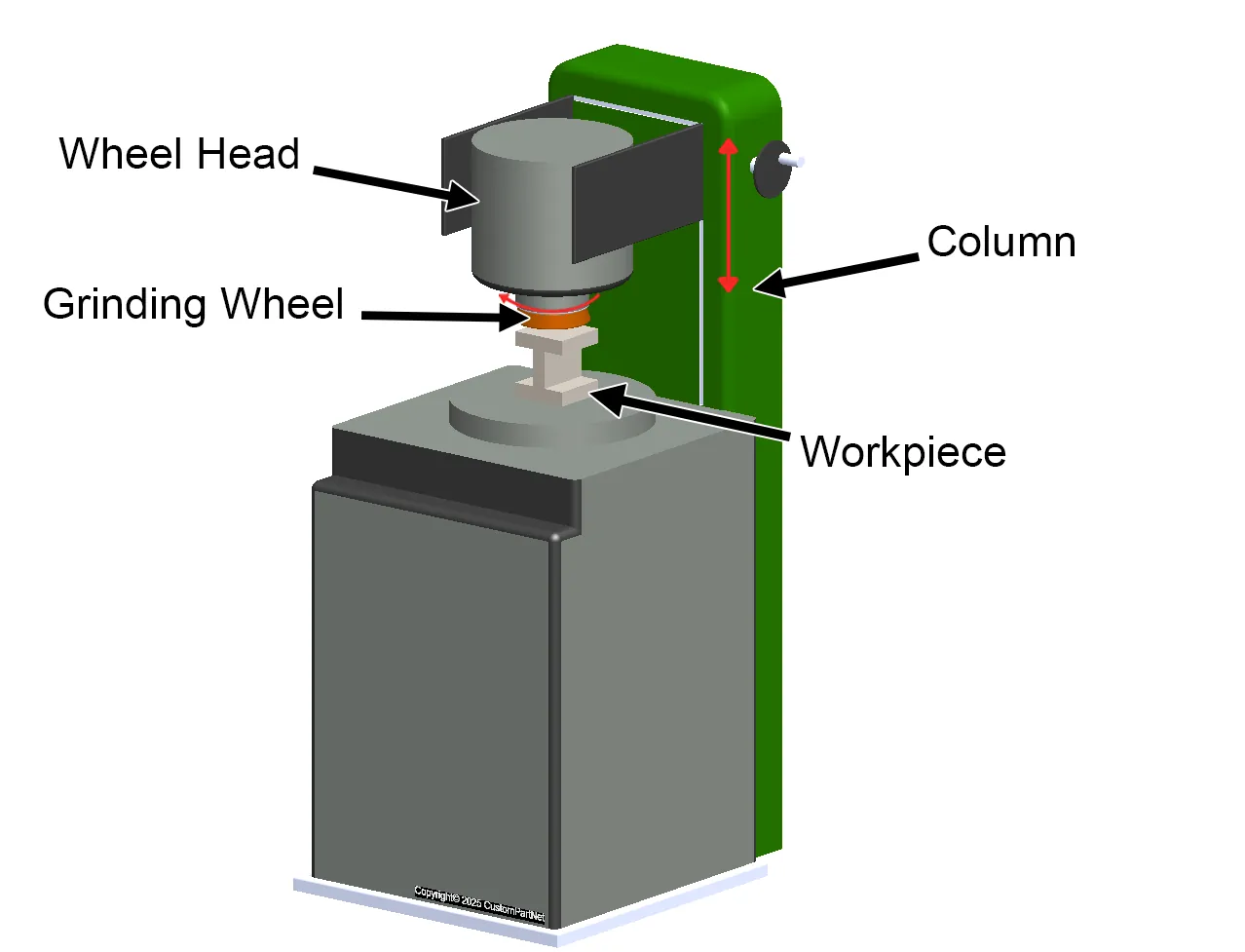

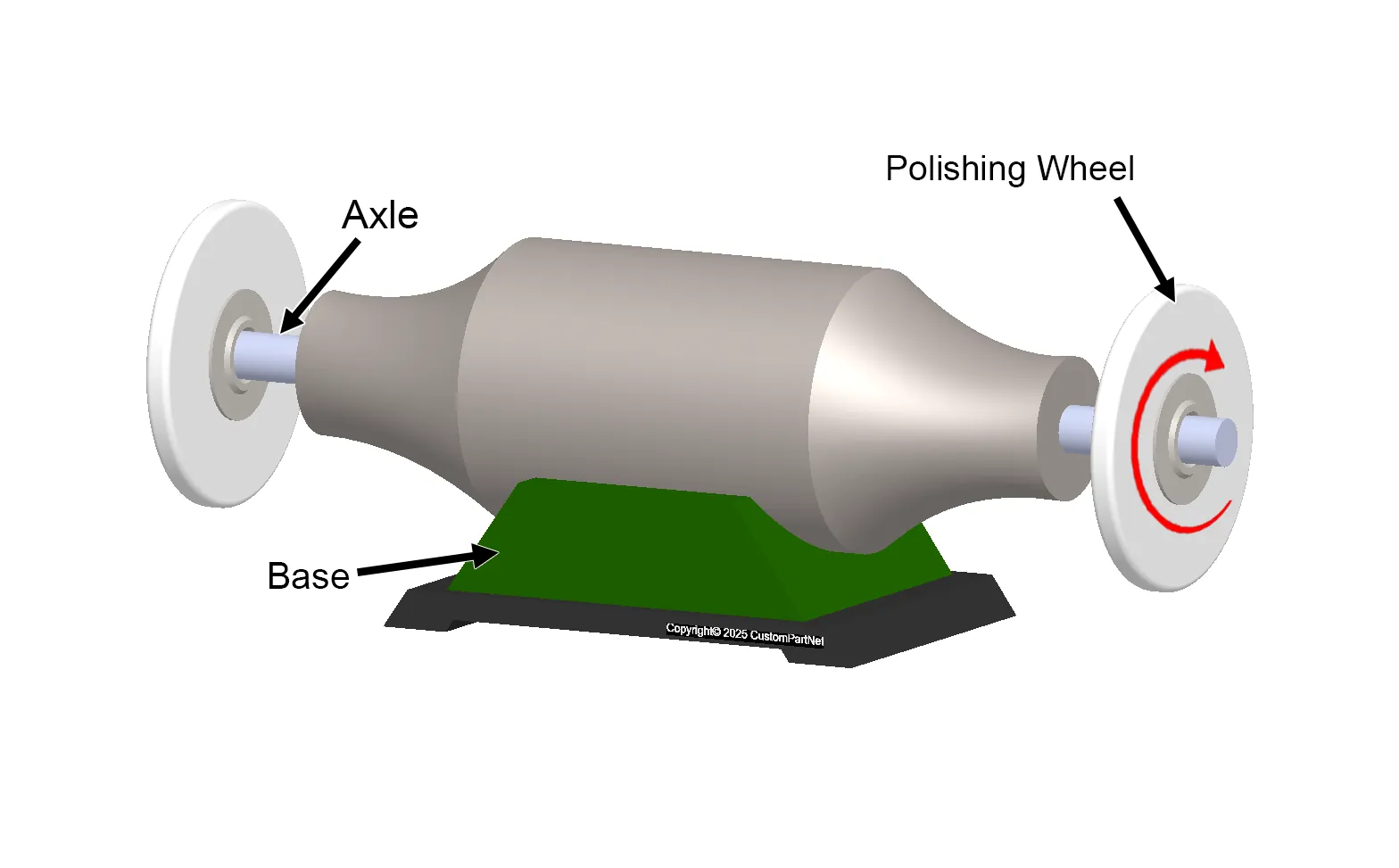

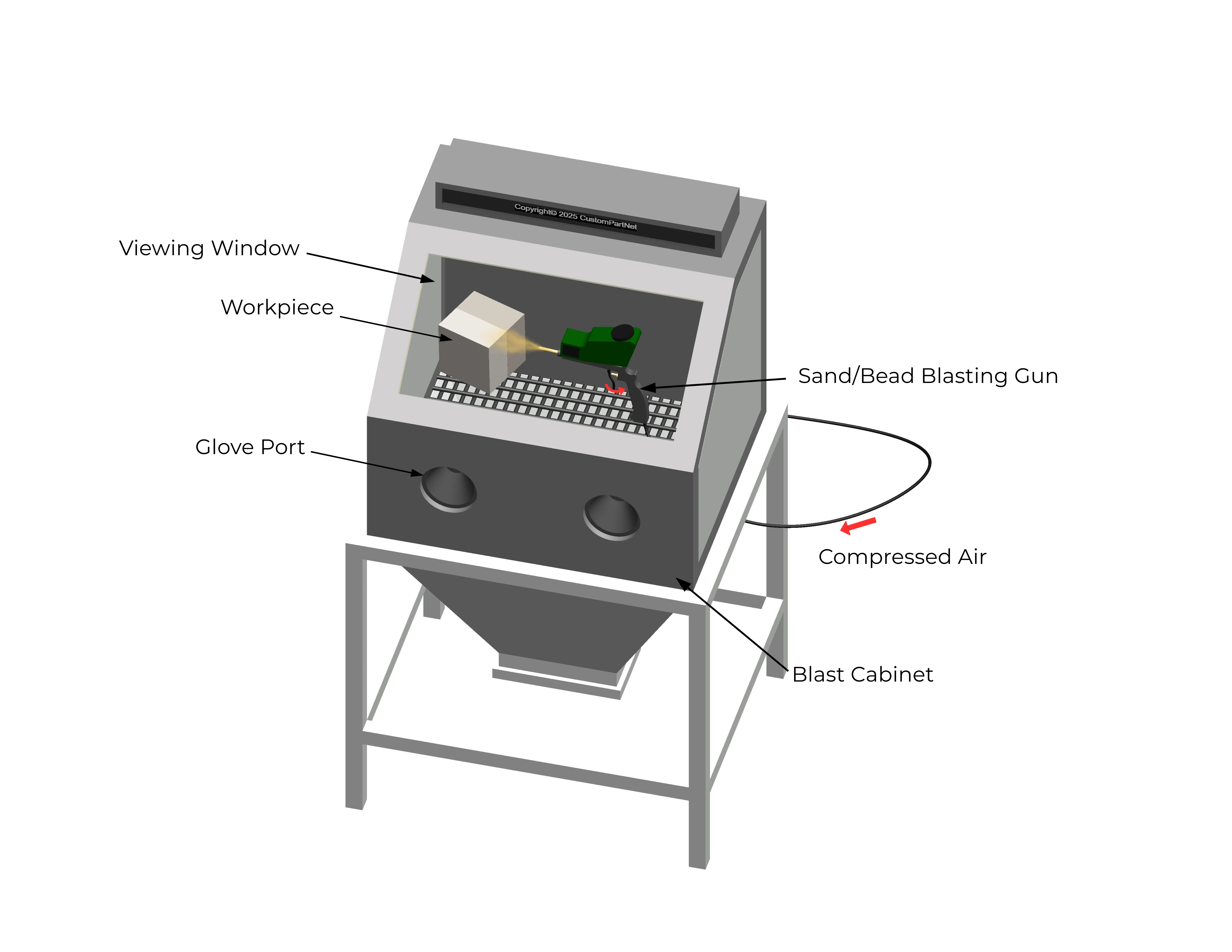

Mechanical finishing operations are used to change the surface texture and appearance of components, enhance dimensional tolerances, or condition surfaces for coating or adhesion. Main operations involve polishing (to achieve high-luster finishes), grinding (to achieve dimensional accuracy and surface smoothness), and blasting (for cleaning or texturing). They are utilized widely in the automobile, aerospace, medical, and consumer products industries.

Process Cycle

- Initial surface inspection and cleaning

- The setup and operation require fixturing

- Surface treatment or material removal (manual or machine)

- Optional intermediate measurement

- End-of-process drying or cleaning

- Final verification and surface inspection quality

Equipment

- Cylindrical or rotary surface grinders

- Buffing/polishing compounds and wheels

- Abrasive belt machines

- Sandblast pressure systems and cabinets

- Ultrasonic cleaners (for end-of-process cleaning)

- Robot or CNC finishing equipment to provide consistency

Tooling

Primary:

- Grinding wheels (vitrified, resin-bonded, and diamond)

- Abrasive pads and belts

- Polishing wheels and compounds

Secondary:

- Jigs and part holders

- Dust/fume extraction units

- Pressure nozzles (blasting)

Materials

| Base Material | Compatible Methods | Surface Results |

|---|---|---|

| Stainless Steel | Grinding, Polishing | Mirror to matte finish |

| Aluminum | Blasting, Polishing | Bright or textured surface |

| Cast Iron | Grinding | Dimensional precision |

| Ceramics | Fine grinding | Smooth, low-porosity finish |

| Plastics | Buffing, Polishing | Glossy decorative finish |

Possible Defects

- Excessive surface discoloration from excessive heat

- Warpage due to forced removal

- Scratches or swirls

- Uneven texture due to worn-out tools

- Residual abrasive contamination

Design Guidelines

- Round off sharp internal corners to permit tool access

- Use consistent wall thickness to ensure uniform finishing

- Prevent deep, shallow recesses unless post-processing finishing is non-critical

- Sized features to permit fixturing without damaging the finish

- Use generous radii to minimize stress and enhance aesthetic polishing

Cost Drivers

- Surface area and quality of finish needed

- Part complexity and accessibility

- Tooling wear and replacement frequency

- Cycle time per unit (particularly in manual operations)

- Setup and fixturing requirements

Mechanical finishing is critical to functional, cosmetic, and preparatory operations across all industries. Effective process selection, tooling, and design integration provide efficient, high-quality production at volume.