Loading library...

Processes - Plating

Plating

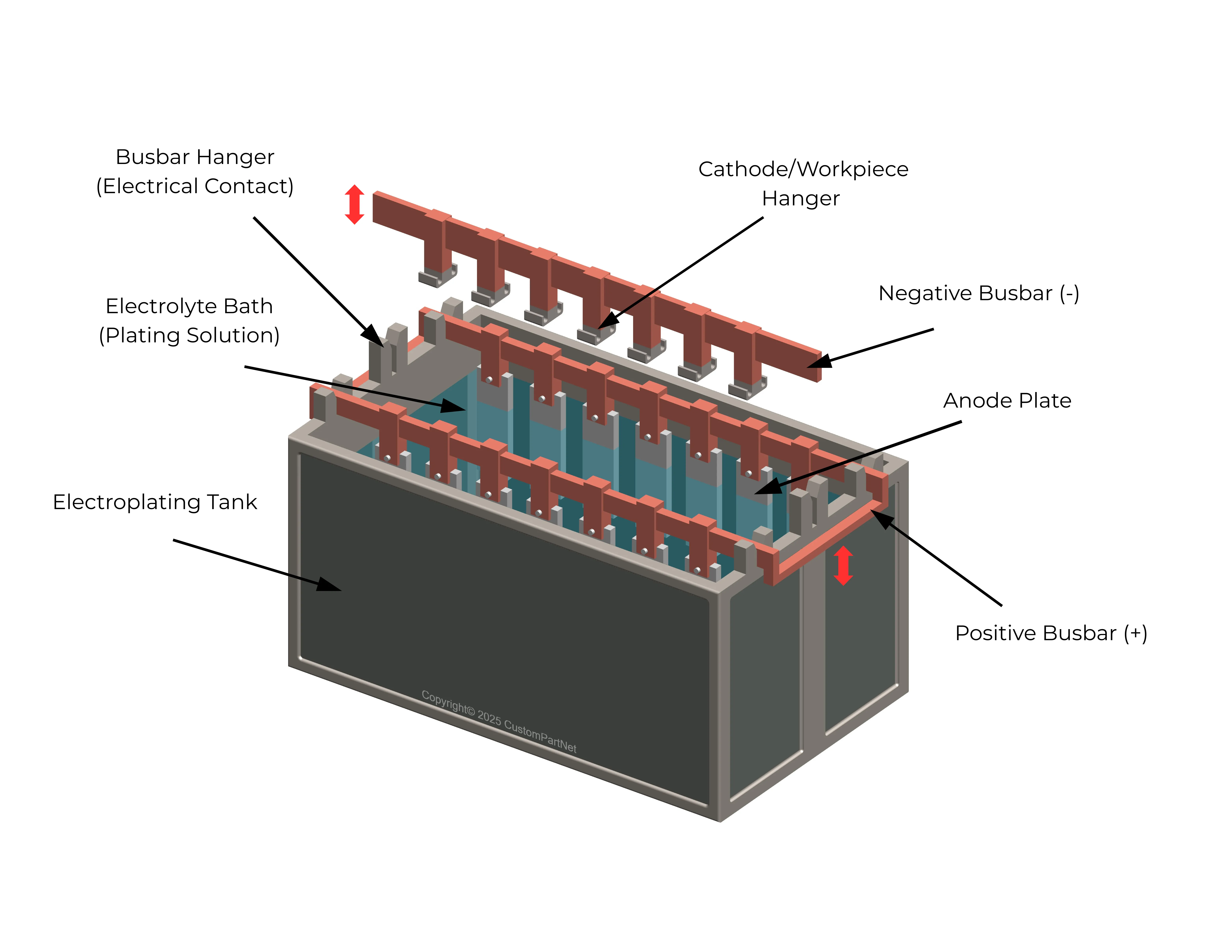

Plating is a surface treatment process where a thin metal layer is deposited over a substrate to provide corrosion resistance, enhance appearance, offer wear protection, or improve electrical conductivity. Electroplating involves the use of an electric current, whereas electroless plating uses a chemical reduction reaction. Both techniques have significant applications in electronics, aerospace, automobiles, and decoration.

Process Cycle

- Pre-cleaning (degrease, ultrasonic, acid dip)

- Surface activation and washing

- Metal deposition (autocatalytic for electroless, electrochemical for electroplating)

- Post-treatment (drying, passivation, rinsing)

- Quality inspection (thickness, adhesion, finish)

Equipment

- Electroplating tanks with rectifiers (DC power supply)

- Anode and cathode fixtures

- Agitation systems (mechanical or air)

- Temperature and pH control systems

- Filtration and chemical dosing units

- Spray and immersion rinse stations

Tooling

Primary:

- Part handling barrel or rack fixtures

- Selective masking plating systems

Secondary:

- Thickness measuring equipment (XRF, coulometry)

- Repeatability inspection fixtures

- Surface conditioning brushes or polishing wheels

Materials

| Plating Metal | Substrate Compatibility | Properties Enhanced |

|---|---|---|

| Nickel | Steel, Copper, Plastics | Wear resistance, solderability |

| Chromium | Steel, Brass | Hardness, corrosion resistance |

| Zinc | Steel | Sacrificial corrosion protection |

| Gold/Silver | Copper, PCB tracks | Electrical conductivity, aesthetics |

| Tin | Copper, Aluminum | Solderability, corrosion resistance |

Possible Defects

- Uneven thickness or inadequate coverage

- Delamination or peeling

- Pitting and porosity

- Overplated or burnt areas

- Poor discoloration due to improper rinsing

- Contamination due to improper bath maintenance

Design Guidelines

- Prevent re-entrant corners or recesses (produces uneven plating)

- Provide an even path of current in electroplating designs

- Use drain holes for internal cavities

- Use masking to limit areas of plating

- Provide dimensional growth tolerance stack-up

Cost Drivers

- Plating metal type and thickness

- Part surface area and geometry

- Batch size and masking complexity

- Process type (manual vs. automated)

- Chemical use and disposal cost

Plating imbues significant value in components by maximizing both functional and aesthetic features. Designed fixtures, bath chemistry control, and pre-treatment procedures imbue consistency and efficiency in industrial plating processing.