- Processes

- Polymer Processing

- Blow Molding

- Injection Molding

- Metal Injection Molding

- Thermoforming

- Metal Casting

- Centrifugal Casting

- Die Casting

- Investment Casting

- Permanent Mold

- Sand Casting

- Shell Mold Casting

- Machining

- Milling

- Turning

- Hole-making

- Drill Size Chart

- Tap Size Chart

- Sheet Metal Fabrication

- Forming

- Cutting with shear

- Cutting without shear

- Gauge Size Chart

- Additive Fabrication

- SLA

- FDM

- SLS

- DMLS

- 3D Printing

- Inkjet Printing

- Jetted Photopolymer

- LOM

- Materials

- Metals

- Plastics

- Case Studies

- Cost Analysis

- Part Redesign

- Product Development

- Resources

- Curriculum Resources

- Glossary

Permanent mold casting is a metal casting process that shares

similarities to both sand casting and die casting. As in sand casting, molten metal

is poured into a mold which is clamped shut until the material cools and solidifies

into the desired part shape. However, sand casting uses an expendable mold which is

destroyed after each cycle. Permanent mold casting, like die casting, uses a metal

mold (die) that is typically made from steel or cast iron and can be reused for

several thousand cycles. Because the molten metal is poured into the die and not

forcibly injected, permanent mold casting is often referred to as gravity die casting.

Permanent mold casting is typically used for high-volume production of small, simple

metal parts with uniform wall thickness. Non-ferrous metals are typically used in this

process, such as aluminum alloys, magnesium alloys, and copper alloys. However, irons

and steels can also be cast using graphite molds. Common permanent mold parts include

gears and gear housings, pipe fittings, and other automotive and aircraft components

such as pistons, impellers, and wheels.

The permanent mold casting process consists of the following steps:

- Mold preparation - First, the mold is pre-heated to around 300-500°F (150-260°C) to allow better metal flow and reduce defects. Then, a ceramic coating is applied to the mold cavity surfaces to facilitate part removal and increase the mold lifetime.

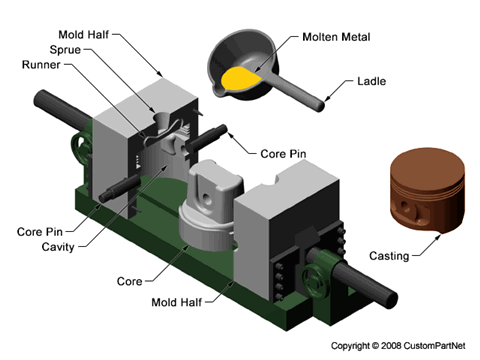

- Mold assembly - The mold consists of at least two parts - the two mold halves and any cores used to form complex features. Such cores are typically made from iron or steel, but expendable sand cores are sometimes used. In this step, the cores are inserted and the mold halves are clamped together.

- Pouring - The molten metal is poured at a slow rate from a ladle into the mold through a sprue at the top of the mold. The metal flows through a runner system and enters the mold cavity.

- Cooling - The molten metal is allowed to cool and solidify in the mold.

- Mold opening - After the metal has solidified, the two mold halves are opened and the casting is removed.

- Trimming - During cooling, the metal in the runner system and sprue solidify attached to the casting. This excess material is now cut away.

Using these basic steps, other variations on permanent mold casting have been developed to accommodate specific applications. Examples of these variations include the following:

- Slush Casting - As in permanent mold casting, the molten metal is poured into the mold and begins to solidify at the cavity surface. When the amount of solidified material is equal to the desired wall thickness, the remaining slush (material that has yet to completely solidify) is poured out of the mold. As a result, slush casting is used to produce hollow parts without the use of cores.

- Low Pressure Permanent Mold Casting - Instead of being poured, the molten metal is forced into the mold by low pressure air (< 1 bar). The application of pressure allows the mold to remain filled and reduces shrinkage during cooling. Also, finer details and thinner walls can be molded.

- Vacuum Permanent Mold Casting - Similar to low pressure casting, but vacuum pressure is used to fill the mold. As a result, finer details and thin walls can be molded and the mechanical properties of the castings are improved.

Return to top

Capabilities

Disclaimer: All process specifications reflect the approximate range of a process's capabilities and should be viewed only as a guide. Actual capabilities are dependent upon the manufacturer, equipment, material, and part requirements.

Return to top | ||||||||||||||||||||||||||||||||||||||