- Processes

- Polymer Processing

- Blow Molding

- Injection Molding

- Metal Injection Molding

- Thermoforming

- Metal Casting

- Centrifugal Casting

- Die Casting

- Investment Casting

- Permanent Mold

- Sand Casting

- Shell Mold Casting

- Machining

- Milling

- Turning

- Hole-making

- Drill Size Chart

- Tap Size Chart

- Sheet Metal Fabrication

- Forming

- Cutting with shear

- Cutting without shear

- Gauge Size Chart

- Additive Fabrication

- SLA

- FDM

- SLS

- DMLS

- 3D Printing

- Inkjet Printing

- Jetted Photopolymer

- LOM

- Materials

- Metals

- Plastics

- Case Studies

- Cost Analysis

- Part Redesign

- Product Development

- Resources

- Curriculum Resources

- Glossary

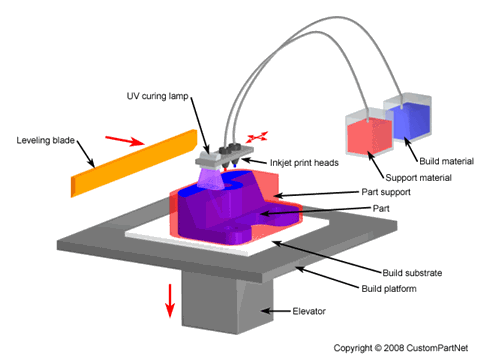

Jetted photopolymer is an additive

process that combines the techniques used in Inkjet

Printing and Stereolithography. The method of building

each layer is similar to Inkjet Printing, in that it

uses an array of inkjet print heads to deposit tiny

drops of build material and support material to form

each layer of a part. However, as in Stereolithography,

the build material is a liquid acrylate-based photopolymer that is cured by a UV

lamp after each layer is deposited. For this reason,

Jetted Photopolymer is sometimes referred to as

Photopolymer Inkjet Printing. The advantages of this process are very good accuracy

and surface finishes. However, the feature detail and

material properties are not quite as good as

Stereolithography. As with Inkjet Printing, the most

common application of this technology is prototypes used

for form and fit testing. Other applications include

rapid tooling patterns, jewelry, and medical devices.

Two companies that have developed jetted photopolymer

devices include Objet Geometries Ltd. and 3D Systems.

The equipment designed by both companies deposits the

photopolymer build material as described above, but

differs in the application of support material. Objet,

an Israeli company, commercialized their PolyJet

technology in 2000. In the PolyJet system,

the support material is also a photopolymer that is

deposited from a second print head and cured by the UV

lamp. This support material does not cure the same as

the build material and can later be washed away with

pressurized water. 3D systems commercialized their

InVision systems in 2003. These jetted photopolymer

devices use a separate print head to deposit a wax

support material. After the part is completed, the wax

is melted away.

Capabilities

Disclaimer: All process specifications reflect the approximate range of a process's capabilities and should be viewed only as a guide. Actual capabilities are dependent upon the manufacturer, equipment, material, and part requirements.

Return to top |