Ejection temperature

The temperature of the material at which a part can safely be ejected from the mold. Ejection of the part before it reaches this temperature may cause warping or other defects.

The temperature of the material at which a part can safely be ejected from the mold. Ejection of the part before it reaches this temperature may cause warping or other defects.

A part defect in the form of small indentations that are made where the ejection system pushed the part out of the mold.

A material that at room temperature can be stretched repeatedly to at least twice its original length and, upon immediate release of the stress, will return with force to its approximate original length.

The percent change in length of a specimen under a given load. Elongation is usually measured within a fixed distance (50 mm or 2 in.) near the point of yield or failure, not over the entire length of the specimen.

Protective covers, or part of such a cover, that fully encloses other parts and may hold them in place. (Includes: boxes, casings, containers, covers, housings, shells, etc)

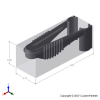

An operation in which an end mill makes either peripheral or slot cuts across the workpiece, determined by the step-over distance, in order to machine a specified feature. The depth of the feature may be machined in a single pass or may be reached by machining at a smaller axial depth of cut and making multiple passes. For a rough operation, the recommended cutting speed and feed are selected for a peripheral or slot cut. A finish operation will lower the cutting feed according to the finish requirements.

End milling (Profile) |

End milling (Slot) |

End milling (Pocket) |

An end milling operation can produce a variety of features, including profiles, slots, and pockets. A profile is a peripheral cut along an external or internal edge of the workpiece with a length equal to the complete perimeter, just one side, or even a part of a side. A slot is a slot cut in the workpiece that can form a complete loop, run through two sides, run through one side, or be contained. Profiles and slots can be machined with multiple steps and by following straight or curved paths. A pocket is a contained feature of any shape that can be machined by either peripheral or slot cuts. Four possible pocket shapes include a cuboid, pyramid, cylinder, and cone. An end milling operation is capable of producing any custom shape, however the total cut length must be known in order to estimate the cost.

Profile: Complete |

Profile: Side (0 ends, 1 ends, 2 ends) |

Slot: Complete |

Slot: Through (2 sides, 1 side, 0 sides) |

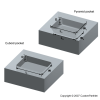

Pocket: Cuboid, Pyramid |

Pocket: Cylinder, Cone |

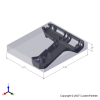

The smallest box, sometimes called a bounding box, that is able to contain the part. The X-Y-Z dimensions of this box describe the maximum length, width, and height of the part. In molding processes, the Z-axis (describing the part's height) is the parting direction of the mold.

Hot glue gun housing (4.38 x 3.75 x 0.59) |

Tongs (6.09 x 2.12 x 2.00) |

Trigger (1.13 x 2.66 x 0.94) |

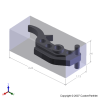

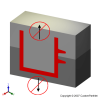

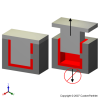

A feature on the exterior of a part that will not allow a mold that contains it to slide away along the parting direction. An external undercut can be either a protrusion or a depression (hole or pocket) and requires an additional mold piece called a side-core to form its shape.

Part with external protrusion |

Mold cannot separate |

Part with external hole |

Mold cannot separate |